Simplify

Standardise processes across the industry to eradicate confusion and complexity, eliminate repetition, reduce costs, boost sustainability and keep the workforce safe.

Standardising and simplifying tasks to benefit safety and efficiency.

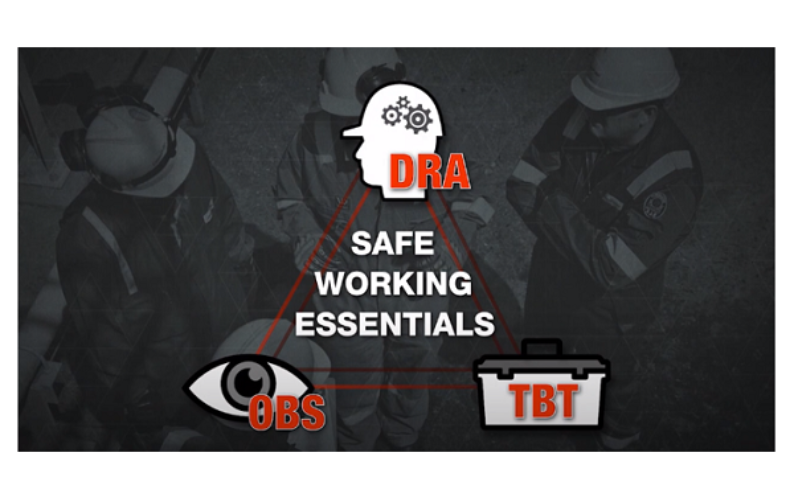

Safe Working Essentials aims to streamline work processes by making them simpler and more engaging for all, while helping to improve safety. It is a suite of standardised tools that covers control of work elements which are fundamental to reducing the likelihood of accidents at work.

Step Change in Safety’s standardised control of work tools provides a common, single approach to specific tasks, removes unnecessary duplication of systems, and creates consistent and efficient safety processes for use onshore and offshore. This unifying approach to tasks can improve procedures and understanding, while generating savings on training time, inductions, effort and costs.

View the process flow diagram to see how the suite of tools fit into the control of work process, download our quick start guide to Safe Working Essentials, or watch this short explanatory film.

To contact the Safe Working Essentials work group, e-mail info@stepchangeinsafety.net

The Safe Working Essentials control of work tools are currently used at over 90 sites, reducing the number of different systems in use. This simplified and standardised approach to control of work systems has:

The key elements of Safe Working Essentials are simplify, engage and sustain.

Standardise processes across the industry to eradicate confusion and complexity, eliminate repetition, reduce costs, boost sustainability and keep the workforce safe.

By engaging with oil and gas operators and contractors to review systems and processes, a common best of breed approach can be established that improves efficiency and safety.

To maintain effectiveness, operators and contractors are required to adopt the tools within their local control of work processes and share lessons with the industry.

To enable the effective delivery of the control to work process and the completion of the task, the following seven steps are incorporated into the Safe Working Essentials toolkit.

The Safe Working Essentials work group was established after it was identified that approximately 5.3 million man-hours can be released over the course of a year by simply saving an offshore worker one hour in their working day. This can be achieved, in part, by standardising control of work tools across the oil and gas industry.

The intention is for Safe Working Essentials to be adopted widely throughout the UK oil and gas industry, with additional tools introduced wherever they are required.

The tools have been created by the SWE workgroup – oil and gas industry health and safety experts – collaborating with other sectors, such as the emergency services and military.

To align with the global industry, the SWE tools were updated in 2019 to include IOGP’s (International Association of Oil & Gas Producer) life-saving rules.

The workgroup has also created e-obs, an electronic observation card system which improves feedback and communication on safety observations across the industry. e-obs is designed for the workforce and allows both installation operators and contracting companies to see their respective card data. The aim is to use technology to improve safety learnings and make the industry safer.

e-obs is an electronic observation card system designed for the workforce, enabling users to record safety concerns and examples of good safety practice.

Short films have been created to help you implement elements of SWE

Derek Thomson has 25 years in the oil and gas sector, including senior roles within operations, design and project management for both major Operators and Service Providers. Along with a wealth of industry experience, Derek has a Masters in Project Management.

Currently, Derek is Director of Projects at Global E&C, an engineering, procurement and construction (EPC) service provider to the oil and gas sector. This recent appointment sees Derek as part of Global E&C’s senior leadership team where he has overall accountability for a portfolio of contracts where integrated services, across more than 400 employees in the business, works together to execute projects in the UKCS.

Gary trained in IT analysis & design, gaining significant experience in the oil & gas industry with Mobil North Sea in Procurement & Contracts, later moving offshore into a Logistics position. Progressed into HSE role for several years offshore, returning onshore to provide HSE support for UK NNS, SNS & Norwegian assets, later being appointed into his first HSE Lead position.

He continued to gain broader HSE experience with Talisman Energy, where he was seconded to lead the Production Loss Elimination team to ‘reboot’ the process including a full redesign, software enhancement and development & delivery of training with the offshore teams. Returned to HSE with mandate to develop strategies & plans to prevent hydrocarbon leaks, taking on his first Co-Chair role for the Step Change HCR Prevention Workgroup. Moved to the HSE Assurance Manager role to improve the audit program, ensure value adding execution and promotion of a learning culture. His final role with Talisman (Repsol Sinopec) was leading a redesign of the SMS to eliminate silo activity, develop a new software solution and establish an integrated approach across the business to remove redundant or conflicting elements.

Gary returned to front line HS&E support with EnQuest, developing improvements on Regulatory engagement and internal process development. Moved to Superintendent role leading both the on and offshore HSE team, including extensive redefinition of the support model and individual role to better support the business and work with our Regulators. Gary is currently EnQuest’s Operations HSE Manager, leading his team across three Directorates and continuing to provide advice to both the site teams and leadership onshore.

Gary has a significant level of experience leading teams, dealing with Regulators and Senior Management within all organisations. Very focused on delivery of value, both in his own work and for the processes that his teams follow. He's a firm believer in producing work and content that delivers, removing low value activity to improve efficiency and better motivate my teams in their day to day approach.

Our searchable catalogue of hundreds of Safety Alerts and Safety Moments are all designed as learning resources that can help improve workplace safety.

Events, forums and webinars focused on improving workforce safety. View our upcoming events below.

Read all of the latest news from Step Change in Safety in our newsroom.

The search is on for people and companies who have gone the extra mile to ensure safety remains at the forefront of UK offshore operations.

Helicopter Incident In Norway - STATEMENT

Be the first to receive our news and alerts by signing up to join the Step Change in Safety website